1.Automatic feed, quick and accurate, save manpower.

2.The special designed feed mechanism is accurate and reliable, and the intermediate transport station can choose the type of the necessary type according to the outer diameter of the pipe.

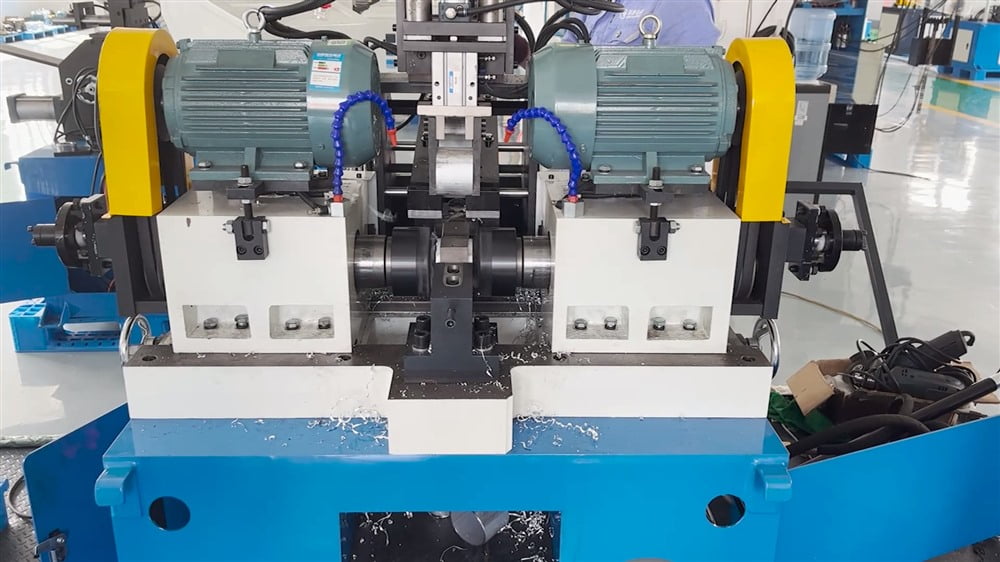

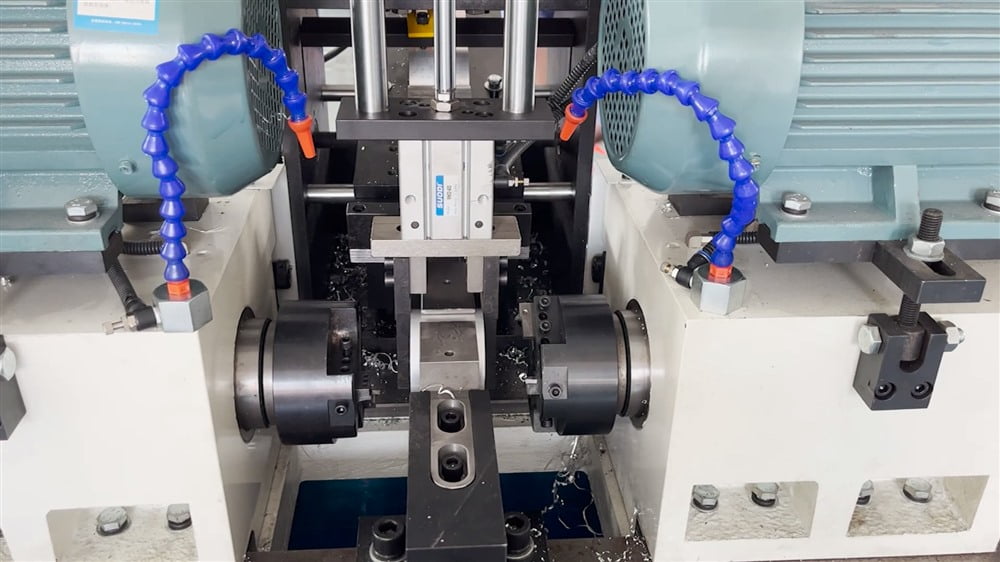

3.Strong head design, power head and motor drive, head fixed. Growth knife life.

4.Use self-centering fixture to ensure the processing concentricity.

5.With the speed of double speed of the shock absorber, it saves working hours, and is easy and easy to adjust and perfect.

6.The system is manual, automatic and easy to debug and use.

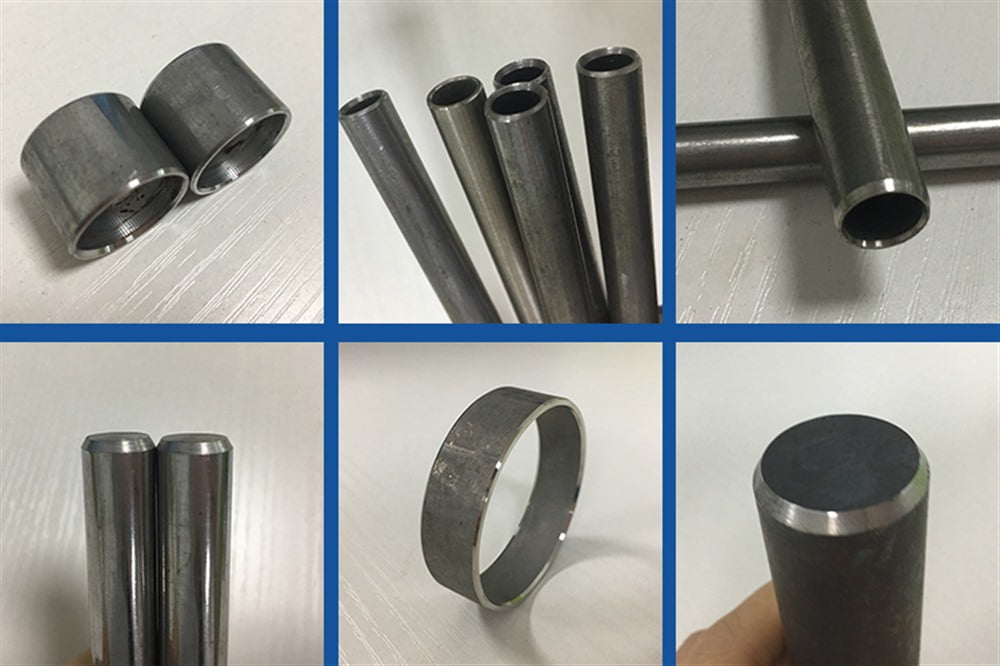

7.End special cutter design, using normalized blade, adjust the knife is simple and convenient, the tube Angle, corner, surface finish in one time, an average of 3 to 10 seconds a (according to the size of the pipe diameter and thickness), fast efficiency.

8.Adapting materials: steel, iron, aluminum, copper, stainless steel, etc.

9.The guide rail in the head of the machine adopts the casting, which improves the precision by CNC processing.