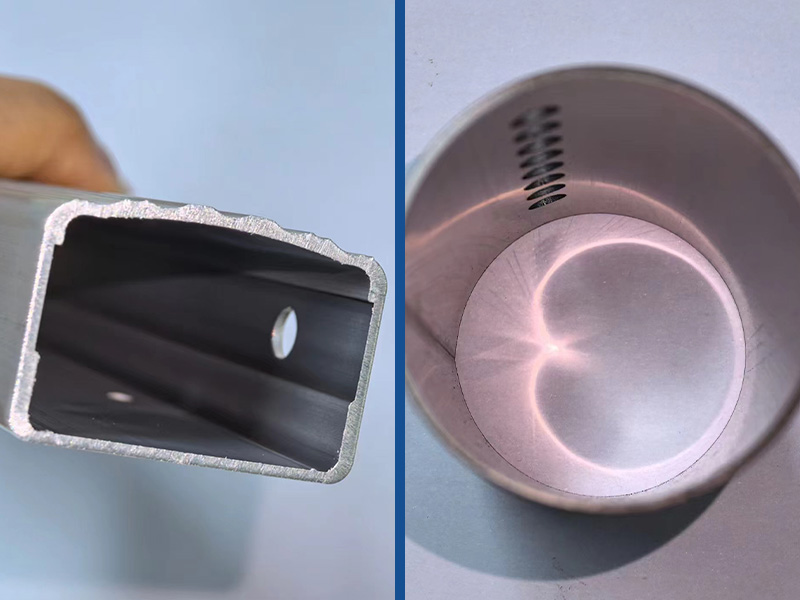

Tube laser cut off machine

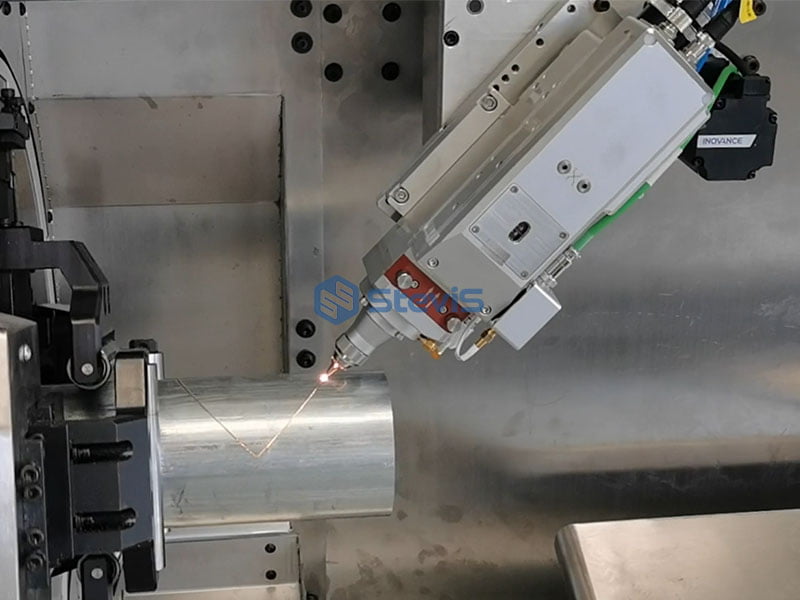

Pipe laser cutting machine

Sheet metal laser cutting machine

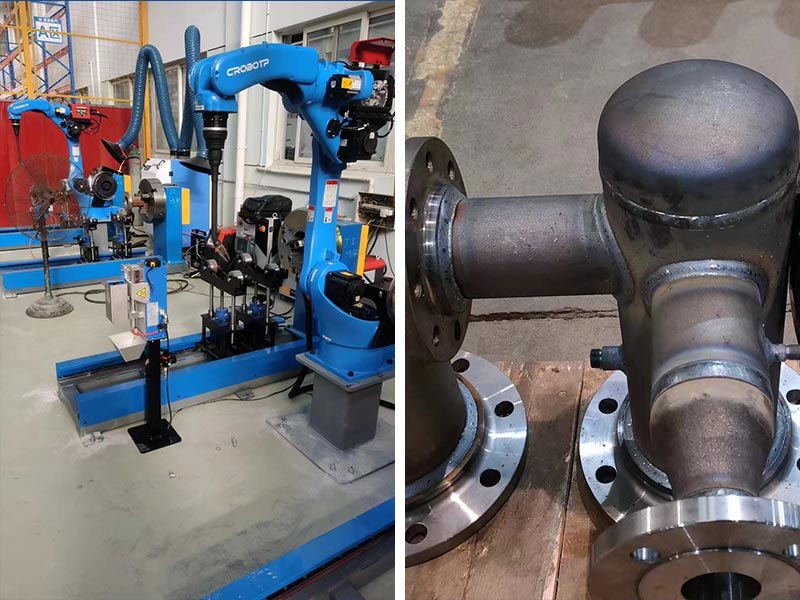

Laser welding machine

Robot Solutions

Customized products & automated production line

Press brake machine

Laser marking machine

Laser cleaning machine

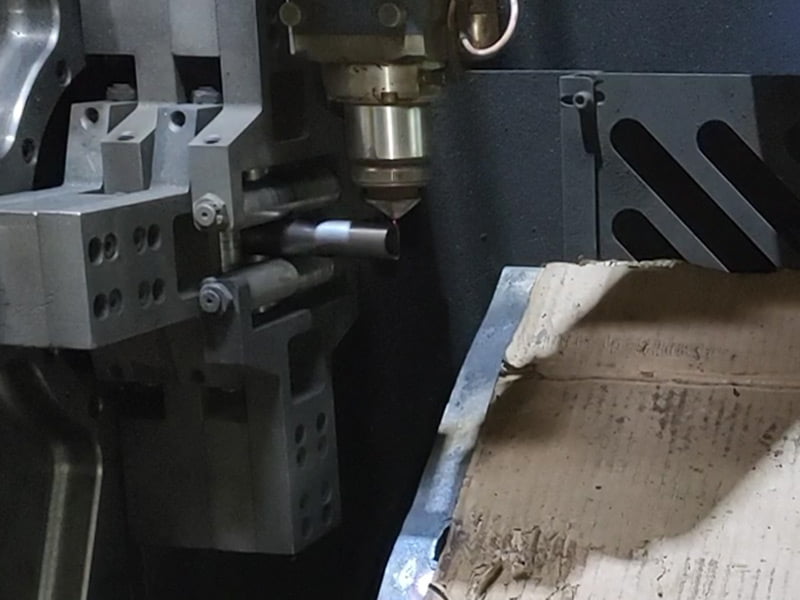

Metal circular saw cutting machine

Pipe & bar chamfering machine

Auxiliary equipment & spare parts

Automotive parts

Metal furniture

inquiry now