P: ¿Cuál es el campo de aplicación de Cobot?

R: No está confinado. Actualmente, la mayor aplicación se encuentra en la industria de estructuras de acero y recipientes; la estructura de soldadura es relativamente simple, como alguna costura lineal, adecuada para productos no estándar.

P: ¿Qué tipos de productos puede soldar el Cobot?

R: Aunque no esté limitado a una determinada industria, es mejor enviarnos fotografías o dibujos de sus productos para encontrar una solución.

P: ¿Qué materiales puede soldar Cobot?

R: Es acero al carbono en perfiles estructurales. Es aplicable a otros materiales siempre que se elija la máquina de soldar adecuada.

P: ¿Cuál es la diferencia al soldar materiales de distinto espesor?

R: Al soldar perfiles estructurales, normalmente se utiliza un robot estándar con un botón de activación rápida. Si el Cobot se va a utilizar en una industria diferente, es necesario revisar si se debe agregar un sensor de torsión y elegir una máquina de soldar adecuada.

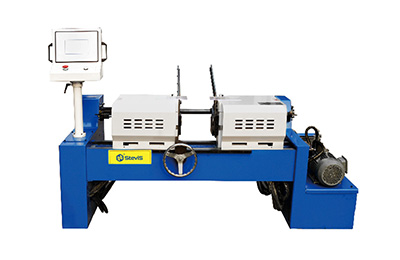

P: ¿Cuáles son los tamaños del Cobot?

R: Los alcances normales del brazo son 920 mm y 1300 mm. La industria estructural y de embarcaciones normalmente utiliza un alcance de brazo de 920 mm con un peso portátil de 22 kg y flexible con base magnética.

P: ¿Cómo permite el Cobot soldar diferentes distancias entre las costuras?

A: Se puede configurar para adaptarlo en el sistema.

P: ¿Cómo permite el Cobot soldar según diferentes requisitos?

R: Se puede configurar en el sistema para diferentes productos.

P: ¿Cuáles son los ahorros después de usar cobot?

R: Un operador puede supervisar varios cobots. Un cobot equivale a 3 operadores de soldadura. Optimiza la eficiencia de la soldadura y mejora la calidad de la costura de soldadura. Fácil de aprender y fácil de usar.

P: ¿Cuál es la diferencia entre cobot y robot industrial?

R: En la actualidad, Cobot es fácil de usar con perfiles no estándar, lo que no es adecuado para operaciones de soldadura en masa.

El operador puede llevar el Cobot al sitio de soldadura y fijarlo con una base magnética para realizar la soldadura.

Si el producto es estándar para soldadura en masa, sugerimos utilizar un robot de soldadura industrial ya que su sistema está equipado con una técnica de soldadura integral para perfiles estándar.

Pero la ventaja para ambos es que una persona puede supervisar varios robots, lo que mejora enormemente la eficiencia de la soldadura.