Although the sales of full-automatic laser welding machines on the market are very hot at present, there is also manual model type among laser welding machines.

Here we will introduce the difference between automatic laser welding machine and manual handheld laser welding machine.

The features of manual handheld laser welding machine are as follow:

Simple machine structure, easy usage, flexible operation, wide application range (available for various position welding).

But it also has the disadvantages like low production capacity, high labor intensity and bad working environment.

Moreover, manual type is not suitable for welding active metal material, refractory metals and low melting point metals, such as aluminum & titanium.

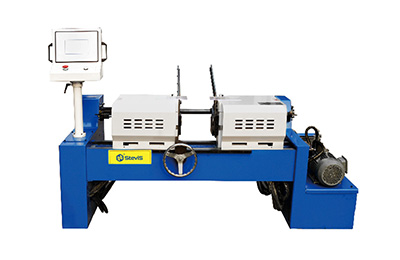

The main features of full-automatic laser welding machine are high production efficiency, excellent welding quality & nice working conditions.

But it is only suitable for straight welding or big diameter round welding with large demands.

Advantages of automatic welding over manual welding:

1. The welding speed is faster. The quality consistency is good with beautiful surface, and there is no uneven phenomenon like handheld welding has.

The full-automatic welding machine can avoid the influence of various human factors during manual welding, such as the influence of the operator's mood, physical condition and proficiency, so as to ensure the consistency and reliability of welding.

2. Reduce the management difficulty and product cost, and reduce the number of operators and inspectors.

Now, with the labor cost increasing year by year, the annual recruitment is the most troublesome thing for the boss.

The fully automatic welding machine can greatly reduce the employment of personnel, greatly reduce the product cost and improve the product competitiveness.

3. The reliability of automatic welding machine is much higher than manual welding.

And the welding effect will not be affected due to human reasons.

4. High intelligence. On the basis of saving labor cost and improving welding efficiency, the full-automatic welding machine can be combined with welding robot system and intelligent control system.

It can automatically adjust the welding current and welding gun attitude in real time according to the data of molten pool state, groove shape, gas flow and so on.

The robot automatic welding machine can also be built with multiple sets of welding expert databases.

5.The full-automatic laser welding machine only needs to manually take and replace consumables, and the operators can work directly with simple operation training, so as to greatly reduce the training cost of technicians.

6. The full-automatic welding machine can work continuously without the emotional and fatigue problems of similar operators.

7. The use of automatic welding machine can avoid worrying about the difference between off-season and peak season.

The above is the difference between automatic laser welding machine and manual welding.

It can be seen that the difference is still very large.

Generally speaking, manual welding is more suitable for personal or small-scale processing, while automatic laser welding machine is more suitable for the needs of mass production in the factory.

In short, you still need to make a purchase choice according to the actual situation.