Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

Customer U is one of the largest stainless steel railing and steel gate manufacturers in Slovakia.

Before purchasing our laser tube cutting machine, they were using an universal type pipe and profile laser cutting machine.

However, they faced a challenge with material wastage because of long length remain of cutting pipes. As a result, the client decided to explore alternative options.

The customer learned about our cost-effective laser tube cutting machine through our company's official website.

They were particularly impressed by the fact that our ST-FL80F series fast automatic laser tube cutting machine could minimize cutting waste, with a minimum length of 40 mm for the tail materials.

Additionally, they found that our laser tube cutting machine could prevent scratches on the processed workpieces.

Although the customer did not have the opportunity to visit our factory in person, we arranged a live broadcast to showcase the machine's appearance, structure, and processing capabilities, as well as our equipment production workshop. This live broadcast helped deepen the customer's impression of our company.

After watching our live broadcast, the customer decided to purchase our laser tube cutting machine.

Machine test video:

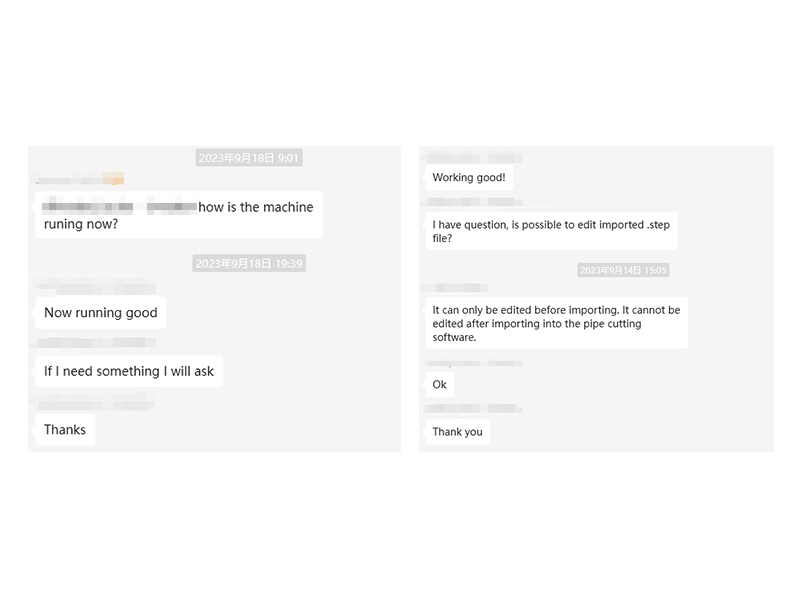

They have been using the equipment for over 8 months now and have been able to operate it smoothly with the guidance of our after-sales team.

Machine in customer's factory workshop:

Related products

E: info@stevistech.com

service@stevistech.com (service)