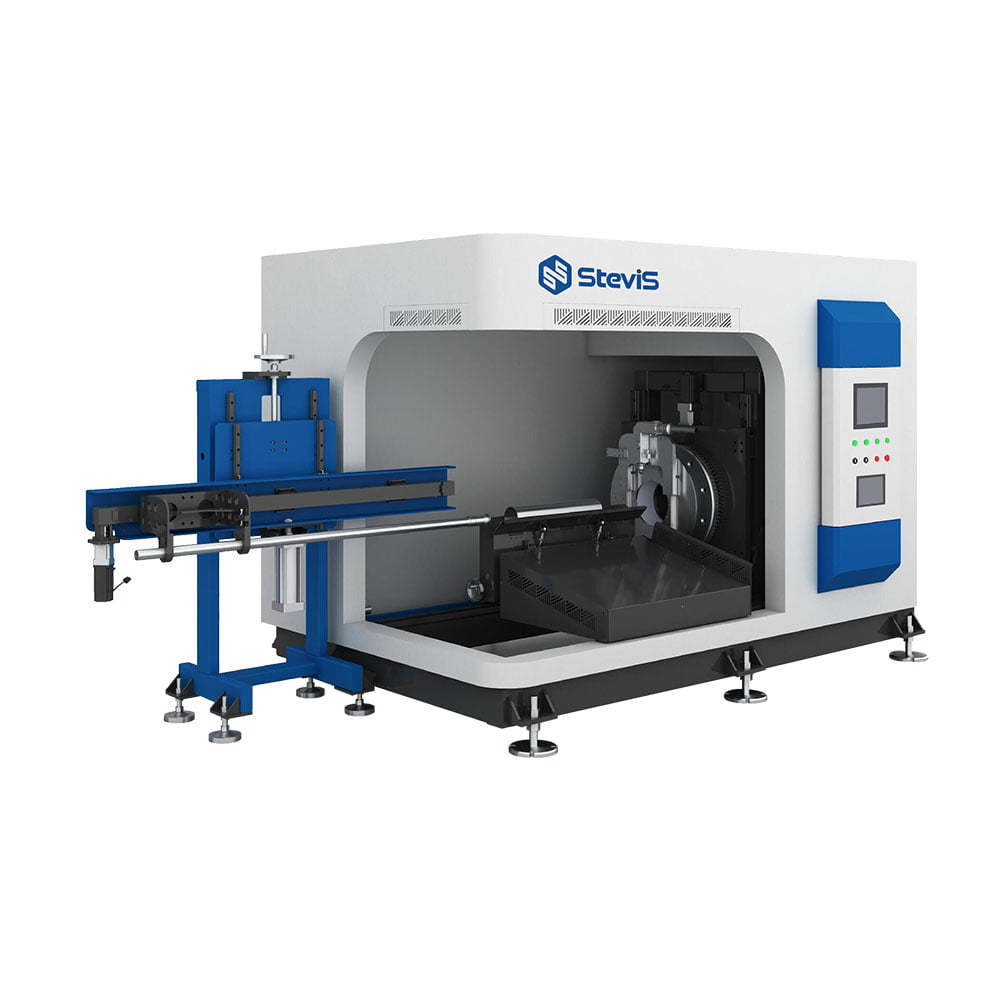

Fully automatic laser cutting, specially for using on tube mills

- Offer finished workpiece by one time cutting, no need secondary cutting processing

- No deformation, burr-free cutting, high accuracy

- No cutting tailings, save labor and material costs

- No need transfer site

Laser 360 degrees surround cutting

- The laser head is L-shaped, the wire has a track and is wrapped with flexible material, which ensures the minimum bending radius of the fiber wire.

Positioning cutting length with high accuracy encoder

- Using incremental encoder, long transmission distance, automatic clearing after each cutting

- The encoder clamping angle is adjustable to avoid the welding seam, and has smaller encoder wheel movement.

- It uses servo and rack for synchronization structure, can offer high cutting accuracy and fast return speed.

Special self-centering electric three-jaw chuck

- The self centering chuck can ensure the tube center is perpendicular to the laser head to the greatest extent so that to reduce the cutting slope.

- It's convenient to set the machine for different tube diameters by touch screen.

- The clamping force can be controlled, so the pipe surface will not be damaged.

Laser head height follow up function

- To ensure the cutting quality, the laser head is equipped with a height adjustment system

- When the pipe is out of round or slightly bent, the height adjuster can adjust the distance between the laser head nozzle and the pipe surface in real time, so as to reduce the cutting slag hanging on the edge and ensure its smoothness

Special anti-spatter function

- To ensure the cleanness of the pipe, it uses the slag rod to collect the cutting slag. The front part of the rod has honeycomb holes and the end is connected with the turbine exhaust fan, so as to avoid the slag stick on the tube inner wall and be exhausted at the same time.

- The reciprocating motion of the slag rod is controlled by the servo, and the distance adjustment is controlled by machine system.