Q: What language is the operation interface available in?

A: Currently there are two languages: Chinese and English .

Q: What types of lasers are available?

A: There are two options: single fiber laser and compound laser.

Q: How do I determine which laser is right for me?

A: For industrial tubes, it is recommended to use a single fiber laser because of its high welding strength; for decorative tubes, it is recommended to use a composite laser because of its fast speed and suitable for those with low strength requirements.

Q: How fast do the two types of lasers decay?

A: Single fiber laser power attenuation is very small within 100,000. After 100,000 hours, the attenuation increases by 3-5% each year. The power attenuation of a composite laser increases by 3-5% each year.

Q: Compared with traditional argon arc welding, what are the advantages?

A: Online laser welding is faster , has higher welding strength, better stability, and longer continuous working time. One person can operate 8 machines .

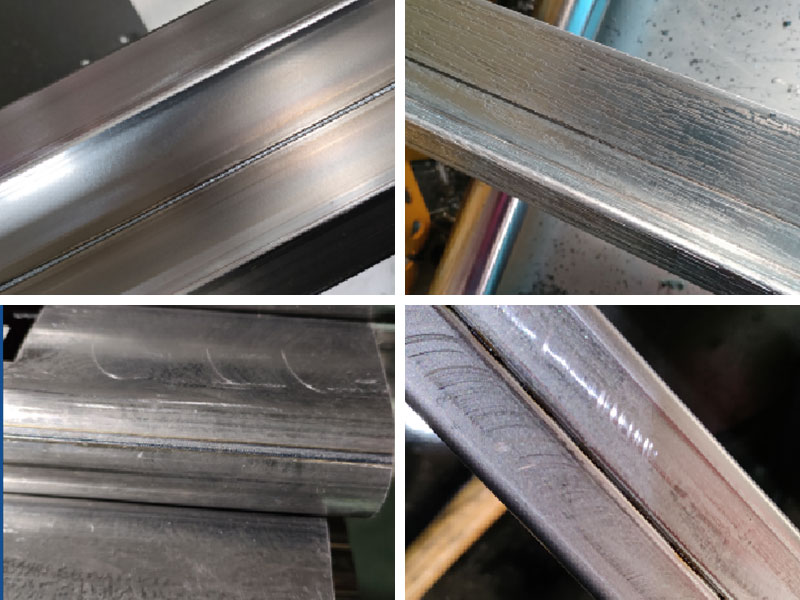

Q: What is the difference between your laser welding and others?

A:

- The welding head is independently developed and produced (including parts, lenses, etc.), with better technical control and welding effect. According to the production data fed back by customers, our equipment can work continuously for 28 days and 24 hours without stopping.

- We have rich welding experience and technology. We have corresponding welding heads for different materials and tailor-made welding solutions for you.

- As for the extremely small tubes and capillaries with a diameter of 6.35-12mm, we can not only weld them, but we can even guarantee to weld 10,000 meters without stopping the machine and without leaking any welds.

- The defective rate of general pipe fittings on the market is 8/10,000 or even higher, but we can control it to 5/10,000.

Q: How to operate the machine?

A: The operation is very simple. You just need to adjust the welding power and move the laser head up and down to the position where welding is required.

Q: How to adjust and determine the appropriate welding power?

A: The welding power needs to be determined according to the speed and thickness. It is recommended to start from low speed and low power and adjust to the appropriate power.

Q: I don’t know what power machine I need to buy for my workpiece?

A: We have a professional team of technical engineers to analyze and make appropriate solutions. You only need to provide the purpose, material, size, thickness and pipe size of the workpiece.

Q: What materials can be welded?

A: In theory, other metal materials such as stainless steel, carbon steel, aluminum, etc. can be welded except copper. You can provide workpiece information and we will analyze and make a solution.

Q: What is the welding speed?

A: The welding speeds for different materials and thicknesses are different . Please contact us for further communication and we will make a suitable solution based on your needs.

Q: Laser head independent is independently developed, How can we ensure that it’s good?

A: Our products have been verified by the market, and we are honored to be BYD's supplier. Because the quality of welding heads on the market is uneven and does not meet our welding requirements, we have formed a technical team to develop and achieve better welding quality and welding effect than the laser heads on the market, and help customers control the defective rate of tube fittings to a level lower than the market level.

Q: How to deal with the laser head after-sales?

A: If the laser head is damaged due to non-human factors, we can provide a replacement laser head.

Q: How to do daily maintenance?

A: You only need to replace the laser head lens and the water in the chiller regularly.

Q: How long does the installation and commissioning service take?

A: As long as water, electricity and gas are prepared, installation and commissioning only takes 1 day.

Q: What should I do if the machine breaks down? Is there a local repair center?

A: Our engineers provide 24-hour online technical support to analyze and solve machine problems. If it is confirmed that the problem is not caused by human factors, we can provide a replacement service. We have service points in many countries, please contact us for further information .